Buckley Society Magazine Issue Five: Buckley and Its Connection with the Mercantile Marine by J.B."

Buckley

October 1979

Buckley Society Magazine Issue Five, October 1979

p. 11 - 14

BUCKLEY AND ITS CONNECTION WITH THE MERCANTILE MARINE

In 1970 I found a clay-encased block of wood, the lower surface of which bore an iron plate. In reverse lettering appeared the words 'Scottish Chieftain' in bold relief (Fig. 4), It resembled a clay-ware stamp which could be used for embossing words on clay or unburnt bricks by hand. The late Mr. George Lewis, retired managing director of the Castle Brick Company, examined the object and was of the opinion that it was a 'ship' stamp. He informed me that during the coal-fire ship era (which virtually ceased in the 1920s), it was the custom of his company to supply ship-repair companies with specially shaped firebricks to fit the individual furnaces of specific merchant ships. Many ships had their own particular measurements of furnaces, to fit the boat's measurements. On returning from voyages, they often required new furnace linings. In order that work could proceed to a tight time-schedule, sets of furnace and flue bricks were made beforehand in anticipation of use on a particular boat. So that the correct batch of bricks were available, they were often embossed with the name of the particular ship for which they were made. Some ships, especially those of a particular class, were adapted for standard sizes of bricks, and in this case un-named standard blocks were used and went by the name of 'standards'. It was quite possible, he added, that this particular stamp related to a coal-fired boat named 'Scottish Chieftain'. He well remembered a glut of fireclay blocks, all bearing ship names on their faces, when coal-burning boats were withdrawn. They were used, he concluded, as hard core for the road to the Trap-works from Pinfold Lane, when it was repaired some years ago.

These views were strengthened when, some time later, I discovered a fireclay 'runner' bearing the imprint 'R.A. THOMAS, 6, Wapping, Liverpool' in a ditch near the Trap-works. Mr. L. Burman of the Liverpool Museum kindly informed me that this company were 'ship cementers' with premises at Liverpool at the end of the nineteenth century. I was unable to find any further information regarding this link between Buckley firebricks and the Merchant Navy until recently.

A short time ago I was allowed to peruse an old order book of a now-extinct brickworks, covering the period 1919-25. I soon observed numerous recurring entries of orders from a ship-repair firm, whose premises were established on a shipping wharf in Limehouse, London. They also appeared to have working establishments at the Victoria and Albert Dock, London, as well as at Newport (Gwent) and Cardiff. The items ordered by this firm were for fireclay goods for coal-fired steamers. In this book, orders were made at frequent intervals for items for specific boats and shipping concerns. Occasionally these were in the form of an advance notice, sometimes as much as six weeks ahead: sometimes they were marked 'Urgent -for immediate delivery, from stocks in hand'.

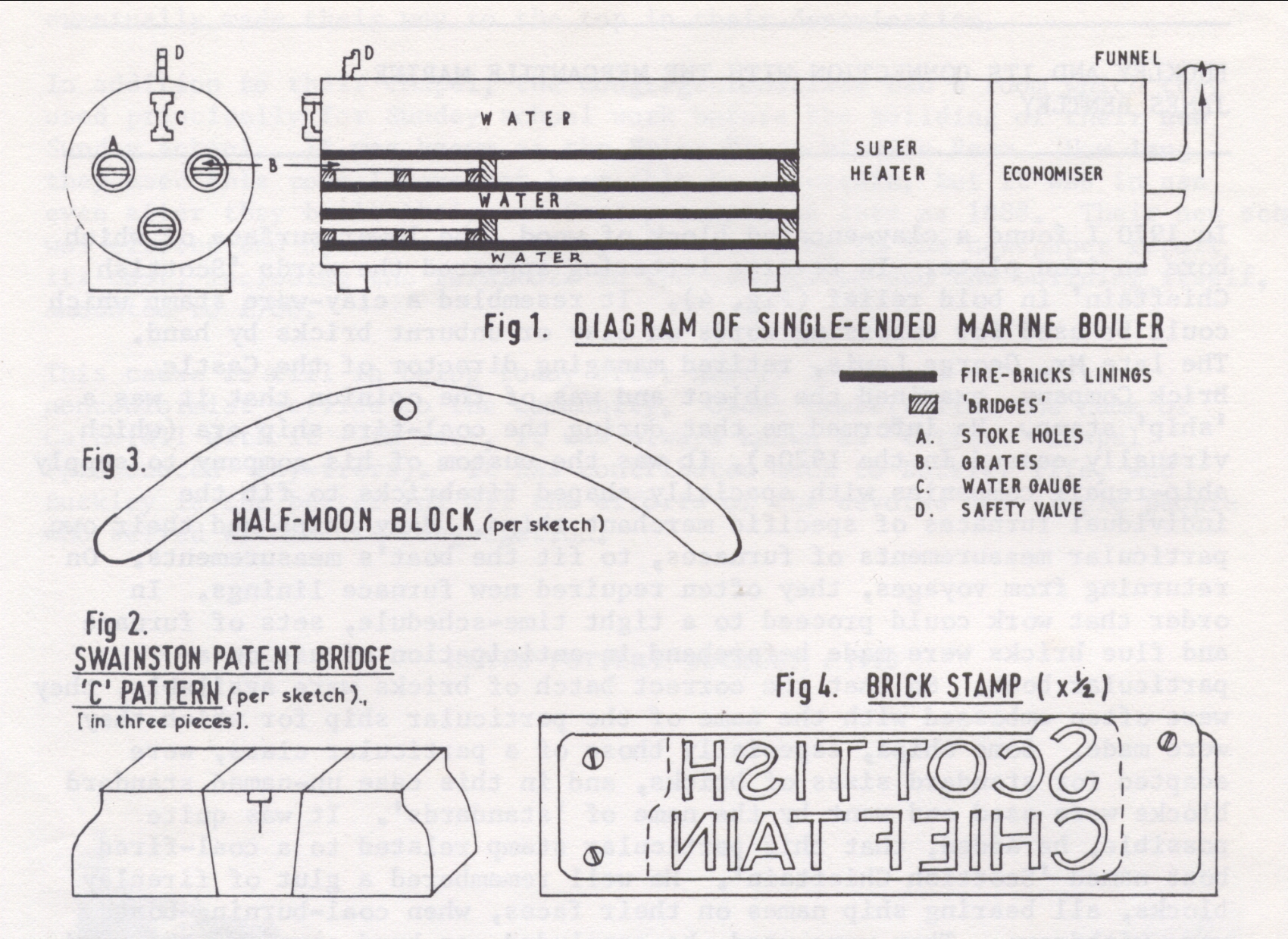

These entries give a vivid record of the world-wide distribution of Buckley firebricks and of their use by the leading shipping lines of the country. Other Buckley brickworks appear to have held similar type of accounts with shipping firms, so that it is quite possible that at any one period, pieces of Buckley clay rested in every port of the world, and traversed every ocean during the heyday of Britain's shipping monopoly. The names of the items ordered often referred to the use put to them; 'Bottoms', 'Tops', 'Sets', 'Standards', 'Firebricks'; Swainton's patent Bridges' are frequently named. Sometimes a rough sketch was attached to the order of the block needed (Figs 2 & 3). Occasionally the actual measurements were included.

To understand fully the need for fireclay linings in ship furnaces, a brief description of the stoke hole is needed. (Fig.1), Ships' boilers were situated in an isolated section of the ship as near the keel as possible. Several cylindrical iron boilers with two or three cylindrical iron tubes passing through them from one end-face to the other were used to raise steam. The boilers contained water, and the tubes passing through them were adapted at one end as a fire-grate. The fires and the burning gases traversed the tubes and heated the water which surrounded them on every side. Fires were burnt directly against the metal lining of the boilers; scale, acid vapours and moisture would quickly corrode the valuable copper walls and leakages and explosions result. Hence the first few feet of the fire tubes running though the boiler would be used as a fire-grate. An iron grid or grate would cross the diameter of the tube over this length. The lower half would be lined with fireclay which extended to the base where a flat surface would be laid. Above the grate, curved linings of fireclay would cover the metal tube and these would extend to the end of the grate. A baffle of end-blocks would delineate the grate area, and the rest of the flue would be entirely lined with fireclay blocks.

The wear and tear of these blocks must have been immense when one remembers that continuous journeys of four to six weeks duration were common. These furnaces raised steam at 200 lbs per sq. inch, and the intensity of flame was increased by the use of forced draught units. The integrity of firebricks and their reliability could not be over emphasized. A feature of shipping procedure was regular overhaul, and the passing of stringent boiler tests, with standards according to Lloyd's survey. That Buckley firebricks appear to have held such esteem in the shipping world for coal-fire boilers, is indeed a high tribute to the quality and standards set by the Buckley industrialists and their employees.

To supply such commodities as firebricks to steamers traversing the world required great foresight and alertness. To carry stocks of individual sets of steamer bricks, for indefinite periods in a brickyard, was out of the question for brickmakers. As a consequence, many astute ways were devised whereby firebricks could be quickly prepared and supplied to a boat on its fleeting call to its home port.

Mr. Lewis told me of an ingenious method of preparing sets of bricks in readiness for Mersey-based steamers, coming for refit. It was (and I believe still is), the custom for steamers to signal their name and destination to the coastguard station at Point Lynas, on the northern tip of Anglesey. This information was then sent by telegraph (and in earlier days of semaphore via several intermediate signalling stations) to the owner's agent in Liverpool. Buckley brickmakers appear to have had an arrangement whereby any Buckley boats passing Point Lynas, were alerted to the brickworks concerned, direct. By the time the boat had docked at Liverpool and the agent had contacted Buckley with instructions for new bricks, the company was already preparing the expected order.

Orders for firebricks came to the brickworks by leisurely letter: "Please increase balance of Highland Warriors from 20 to 30 and delivery in 2 months time", "Port Albany order will not be required until about 8 weeks from this date", Sometimes orders arrived by telegram, "Please despatch at once Very Urgent 50 'Cunard' Bridges and 500 3¼" Stay Nut Covers". Not every order was sent to the customer's satisfaction as is shown in an order dated 4 April 1925:

400 5 x 4 1/2x 9ins. Firebricks

4003x 4 1/2x 9ins. Firebricks

1436x 12x 5ins. Firelumps

1033x 12x 5ins. Firelumps

Please see that the above order is made to sizes, as previous deliveries were very uneven.

One request in July 1925 was for '15 single sets (Female bottoms)' for S.S. Port Brisbane!

Identifiable products include the following:

Swainston Bridges; Swainston pattern; fishtail ends; 'C' pattern Swainston Patent (Fig 2); Nut Covers; Arch-end firebricks; Cone-bricks; Half-moon blocks.

The vessels which used Buckley firebricks listed in the sale book appear to have been chiefly boats engaged in the Australian and New Zealand trade.

The Cunard orders were possibly for boats on the North Atlantic sea routes. Many of the boats were owned by the Port Line and by the New Zealand Shipping Company. Perusing the orders received for named ships' bricks makes it possible to make a rough guess on the active life of the firebricks. This is far from conclusive; some boats were in regular service during the whole period. Some boats covered long distances without a complete cleaning of the fire-grate, and with the fires in use all the time, whilst other ships may have been engaged in short-distance journeys with a break in-between.

Supplies of bricks for boats were examined for approximately twelve months between December 1919 and December 1920. A well-maintained boat appears to have been S,S, Athenic. Earlier references show that this boat was in regular use for a period of twenty-seven years between Britain and Austrialia/New Zealand. During the year under examination, it had overhauls in July and in December as follows:

July 1920 20 sets of 3 'Bridges'

34 'Tops' only

8 'Centre-pieces'

December1920 40 sets of 3 pieces

Alongside the above orders were requests for associated goods such as 'Swainstone', 'Nut Covers', 'Standards', 'Half Moons' firebricks and 'lumps'. The orders for Merchant Navy goods represented only a portion of general trade. Very few of the items were, or could be made, by mass production. Transport of finished goods was almost totally by rail, and completion dates were often at short notice. One may wonder if such prodigious output could be maintained, or even be carried out today.

Author: Bentley, James

Tags

Year = 1979

Month = October

Landscape = Marine

Object = Tools & Equipment

Transport = Water

Work = Heavy Industry

Extra = 1970s

Copyright © 2015 The Buckley Society