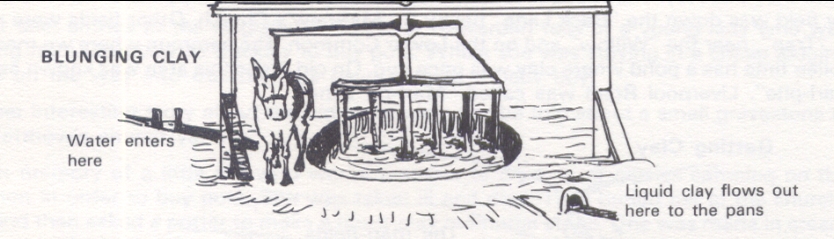

A typical Buckley Pottery blunging pit"

1981

From "A Short Account of the Buckley Potteries" p.17 and 18.

See also 129.2 and 3.180 for accounts on blunging.

...Inside the yard was a small round pit called a "blunger". It was here that raw clay was beaten up into a cream. Sometimes another smaller pit, lined with stone, was nearby. It contained four strong wooden paddles with round stones in the compartments made by the paddles. This was the "lead-jack". It crushed the lead ore and flints which were made into glaze.

A short distance below the croft were two or three shallow ponds. They were connected to the "blunger" by a smal gutter or "Goyt". The ponds were called pans. Here the liquid clay from the blunger ran down the channel into these ponds. It was left here to "settle" and harden.

...The raw clay was mixed with pebbles, grit and even grass and twigs.

In order to purify it down to a smooth, fine clay, it was Blunged.

This means it was stirred up with water, in a shallow pit. A large wooden beam with teeth pointing down into the mixture was turned round a spindle, which were in the middle of the pit. This churned up the clay and as water was added, the mixture turned into a thin cream. Stones and grit dropped to the bottom of the pit. Sticks, grass and straw floated on the surface and were skimmed off. The cream overflowed onto a channel and ran down the hill to enter a series of shallow pools at the lower end of the pottery.

Author: Bentley, James

Tags

Year = 1981

Work = Light Industry

Extra = Animals

Copyright © 2015 The Buckley Society