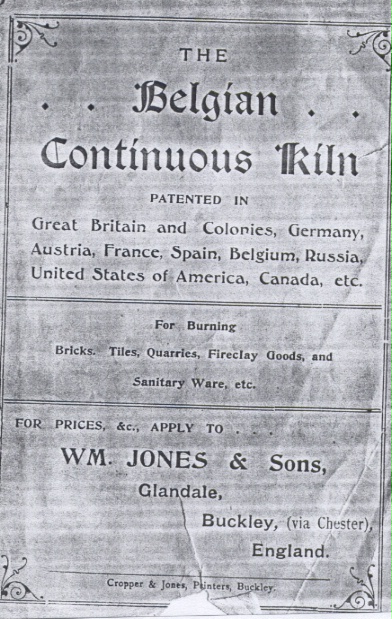

Brochure for Belgian Continuous Kiln"

Glandale, Liverpool Road, Buckley

1907

See Buckley Magazine No.14.

"The Belgian Kiln" by James Bentley. p. 3 - 7.

William ran the firm from Glandale, Liverpool Road ( going down, it is first on the left after the traffic lights). His sons were John William, The Poplars (across the road from Glandale); Samuel of Plas Bistre, Mold Road; and Thomas Edward Jones of Glandale. They all worked in the business.

DOCUMENT TEXT

COVER

THE BELGIAN CONTINUOUS KILN

Patented in Great Britain and Colonies, Germany, Austria, France, Spain, Belgium, Russia, United States of America, Canada, etc.

For Burning Bricks, Tiles, Quarries, Fireclay Goods, and Sanitary Ware, etc.

FOR PRICES, &c., APPLY TO ....

WM. JONES & Sons, Glandale, Buckley, (via Chester), England

........................................................................

PAGE ONE

THE BELGIAN CONTINUOUS KILN

Our principle can be applied to continuous kilns of large and small sizes, as well as to two intermittent kilns. One with two lines of chambers and the other with one line of chambers.

As explained hereafter, the intermittent kiln with two lines of chambers or the semi-continuous kiln is specially recommended for works which, at the beginning, do not produce enough to keep a continuous kiln going, but the output of which is increasing. As required, new chambers are added to the existing ones until their number is sufficient to work continuously.

Our kiln is very durable and its maintenance in order costs very little.

DESCRIPTION OF THE KILN

As shown by the drawings (enclosed), the kiln consists in two parallel lines of chambers A, arched over and connected at their ends by two circular or end chambers B, which at their beginning, take the whole internal width of the kiln, and narrowing down into the opening on the other side.

This arrangement of the end chambers ensures burning there equally as well as in the square chambers.

In each of the outside walls entrances c are left, for the drawing and the filling of the chambers.

PAGE TWO

Opposite each entrance, in the inside of the kiln, on the floor level and on the whole width there is a grate D used as a furnace underneath which is an ashpit E. The fuel is thrown into it through an opening or fire hole F, left in the temporary wall G, built in each entrance when the chambers are filled with goods. A furnace door H is used for opening and closing the hole F.

Sight holes I, are left in the arch for the controlling of the fire; they can also be used for taking hot air from the cooling chambers for the purpose of drying the goods above the kiln.

WORKING OF THE KILN.

All entrances are closed up by a temporary wall, except those of Nos. 9 and 10 chambers through the first of which No. 9, the goods are filled in, and through the second No. 10 the goods are drawn out.

Number 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 1 and 2 chambers have been burnt in succession, and are cooling.

This cooling is effected by the cold air entering through the open entrances of Nos. 9 and 10 chambers. This air strikes first the goods in No. 11 chamber, and carries forward into No. 12 chamber the little amount of heat remaining in them, and so on through numbers 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 1 and 2 chambers, the goods of which are warmer and warmer still. Their heat is thus gradually taken up and carried into N0. 3 chamber which is burning, in order to reduce considerably the consumption of the fuel.

The small quantity of unburnt gases are pulled up to the end of No. 6 chamber where the draught is made. Before reaching this point the gases pass through Nos. 3, 4, 5, and 6 chambers, the goods of which gradually heat up.

When a chamber is burnt off the fire is carried to the next one by throwing fuel into its grate. As it comes within a very high temperature, it burns up at once.

...........................................................

PAGE THREE

ADVANTAGES OF OUR PRINCIPLE

Amongst the numerous advantages of our kiln we will state the following ones:-

1 - Considerable saving of fuel.

2 - Possibility to use several kinds of fuel, owing to the long furnaces, such as small coal, slack, wood, peat, etc.

3 - Easy filling of the chambers as there are no feed holes to leave in the setting.

4 - Easy drying of the goods in advance of the fire.

5 - Very easy working of the kiln.

6 - No nuisance, as the gases are well consumed in the kiln, and scarcely any smoke seen coming from the chimney.

7 - Hardly any repairs as their (sic) are no feed or fire holes to get out of order.

A saving in fuel is realized of 70 to 75 p.c. as compared to the consumption in intermittent up or down draught kilns, of the round or Scotch type, for burning bricks, tiles, quarries, etc.

The saving is greater still for burning fire bricks or such goods that need a higher temperature.

It can be readily understood that such a saving is possible, when one goes carefully into the working of the kiln, and considers that the whole heat of the burnt goods is recuperated, and that the gases escape to the chimney at a very low temperature.

The quantity of fuel varies according to the kind of goods and the nature of the clay. The approximate consumption is 4 cwts. of small coal or slack per 1,000 for ordinary building, and 6 or 7 cwts. for fire bricks.

As we have previously stated owing to the large furnaces wood or peat can be also be used for burning instead of coal. This is a great advantage for works in countries where such fuel is cheaper than coal. In other top fired kilns wood or peat could not be used owing to the small feed holes.

.................................................................

PAGE FOUR

Our kiln gives a uniform burning with good color and no waste, because (1), the draught is always made with the same strength in every part of the kiln, so that the top as well as the bottom, the front as well as the back, and the sides as well as the centre of each chamber are burnt equally. (2), When the fire is brought to a chamber, the burning of the goods therein are already at an advanced stage, and they do not afterwards remain a long time under the action of the fire, and the over burning, with ordinary care, is avoided. (3), Further the coal is not in contact with the goods, as is the case with top fired feed hole kilns, and thus we avoid badly burnt and discoloured goods, and the waste is reduced to the lowest minimum.

Owing to its system this kiln gives a good color if the clay allows for its production; should the goods be set in the kiln in a wet state and a drying or special water smoking is necessary, this can be done slowly and effectually, as we have incorporated a splendid advance drying system whereby the waste heat is utilized for drying the goods in advance of the burning proper. This system is simple and effectual, drying the bottom of the goods first, and carrying out the steam direct from each chamber, and not passing it on through others.

Another feature is that a low or very high temperature can be raised as required - just sufficient to burn flower pots or drain pipes, or high enough to burn the best Yorkshire or other fire clays at a temperature of 3,000, Fahrenheit.

To conclude, it differs from other continuous kilns chiefly because the firing is effected from the bottom floor level into special furnaces, underneath the grates of which air is supplied and controlled as desired, so that perfect combustion always takes place. Further the fuel is not in contact with the goods, as in all other top fired kilns.

.................................................................................

PAGE FIVE

Between each furnace the goods are set. From these particulars it can be readily understood that our kiln is a great improvement on all other continuous top fired kilns, where the fuel is thrown amongst the goods in twenty or more feed holes in the top of each chamber, the results of such firing being inevitably bad colour, imperfect combustion, and very great waste.

The setting in our kiln is similar to that of an ordinary Scotch kiln, as there are no feed hole shafts required, and so the most delicate goods, of all shapes and sizes, can be set without fear of injury from the firing.

Further as there is no firing from the top floor level, this can be utilized for drying purposes, giving a drying floor where any special goods can be dried entirely free of cost, and a space of about 500 square yards.

We shall be glad to show our kiln in operation, burning ordinary and red facing goods, quarries, etc, as well as Yorkshire and Welsh Fire bricks, and blocks of various shapes and sizes.

TESTIMONIALS

The following are specimens of our numerous testimonials:-

Cwmbran Brick and Tile Works, Newport.

Messrs. Wm. Jones & Sons

May 15th, 1906.

Dear Sirs, -

We have now been using the Belgian Kiln you built for us for the past three years continuously. We are getting out red pressed facing and wire cut bricks of a good uniform color. The quantity of fuel (slack) consumed being only one-third of that required for our down draught kilns. We consider the advantages claimed for the kiln have been conclusively proved by the results obtained by us.

Yours truly,

G. W. Williams, Managing Director.

..............................................................

PAGE SIX

Cuckmere Brick Co., Berwick, Sussex.

Messrs. Wm. Jones & Sons.

March 21st, 1907.

Dear Sirs,-

We have pleasure in giving you the following particulars of our Belgian Kiln. The output per week for common and facing goods is 80,000. For common bricks some 91,000, with an average consumption of slack per 1,000 of 4 cwts. The color of the goods is excellent. We shall be pleased to give you any further information.

Yours faithfully,

CUCKMERE BRICK Co.

*****************************

Beckenham and Penge Brickworks, Ltd., Kent House Road, Beckenham.

Messrs. Wm. Jones & Sons.

March 21st, 1907.

Dear Sirs,- In reply to your enquiry, our average burn last year was over 91,000 bricks per week in our Belgian Kiln. Average fuel consumption 5 cwts. per 1,000, with best coloured goods. Proportion about 75 p.c. Waste 11/4 p.c.

Yours faithfully,

BECKENHAM & PENGE BRICK Co., Ltd.

..................................................................

PAGE SEVEN

Southwater Brick and Tile Co., Ltd., Southwater, Horsham.

Messrs. Wm. Jones & Sons.

April 10th, 1905.

Dear Sirs, -

We shall be glad to show any one your Belgian Kiln, which just lately surpassed itself in results, burning deep red facings at 3 1/2 cwts. fuel per 1,000 bricks.

Yours faithfully,

C. H. ALDERSMITH, Secretary Southwater Brick Co., Ltd.

For further information, Prices, and orders to view, apply -

WM. JONES & SONS, Glandale, BUCKLEY, via Chester

Author: Hodnett, Brian

Tags

Year = 1907

Building = Industrial

Work = Heavy Industry

Extra = 1900s

Copyright © 2015 The Buckley Society